Processing

Complete sheet metal cycle

The C.L.M. it is equipped with the best equipment available on the market for sheet metal working and to carry out all the work necessary to give the customer the finished product and packaged.

The production cycle includes the following processes:

Laser cutting

Machines enslaved by automated warehouse. Working area 1500 x 3000 maximum thickness of 3 mm.

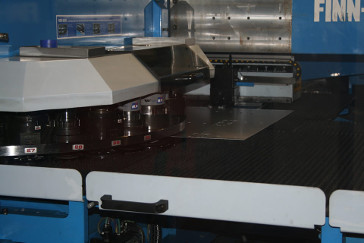

Punch

Related to automate warehouse. Working area 1500 x 3000 maximum thickness of 3 mm. With multi punching press high standard. Workable format max 1250 x 2000 maximum thickness of 1.5 mm;

Spot welding

Spot welding of most particular by spot welding with spot welders and column 2 to projection

Automatic bending machine

With the following fields: side max 2500 mm height 160 mm max fold thickness 2 mm max or max length 2200 mm, height 310 mm max fold thickness up to 2 mm. With the following labour leader: max 2500 mm diagonal side max 3000 mm height 200 mm max fold thickness up to 2 mm;

Powder painting

With twin rail conveyors equipped with 2 cabins, for application of powder epoxy, polyester, metalized, silicon for high temperature, after alkaline degreasing and rinsing with osmosis water. Maximum size of the building painted 2650 x 2200 x 600 mm, max weight 100 kg;

Assembly and packing

Assembly to customer specifications of electromechanical parts, insulators, and accessories. Packing according to customer specifications in cartons or on pallets in iron.